Good wear resistance.

Good breathability.

Geometric stability.

The blade is neat and tidy.

Long service life: 600-650 working days or 50 million meters of cardboard.

The surface is flat and the markings are clean.

Hot pressing and flocking joints.

Highly hygroscopic and hygroscopic.

Low noise.

Fast operating speed.

The leader when it comes to corrugator belt.

As a market leader in corrugated machine belts and fluidized fabric technology, Dragon represents the highest quality innovative products. Our flexibility in development and production allows us to produce special products based on customer specifications beyond the standard product range.

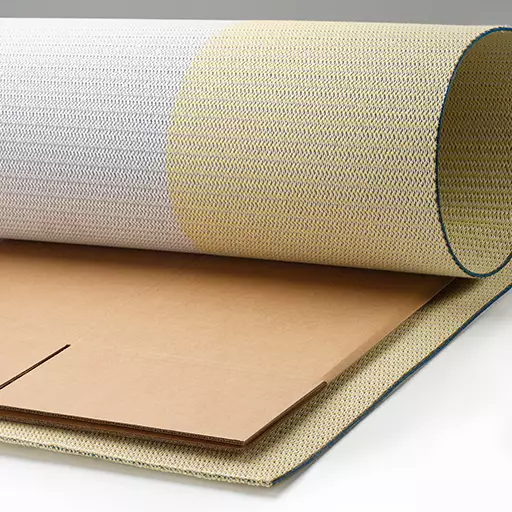

Dragon corrugated machine belt is specially developed for double-sided machines in corrugated systems. Their main task is to transport corrugated cardboard smoothly and dry it as well as possible. The belt is subjected to enormous stress from temperature, contact pressure, friction, tensile stress, and moisture.

The Dragon corrugated conveyor belt is composed of multiple layers of fabric. The tear resistant, heat-resistant, and wear-resistant fibers give the belt excellent motion and transportation characteristics. This ensures safety and reliability during the production process.

The Corrugator Belt (Corrugated cardboard conveyor belt) produced by DRAGON company is specifically developed for double-sided machines for corrugated cardboard production lines and raw materials. Produced by experienced engineers using our advanced equipment. DR AG ON The Corrugator Belt (Corrugated cardboard conveyor belt) produced by the company is widely used and suitable for all known tile line models in the world! Especially in the use of new high-speed corrugated machines, the most significant results have been achieved. What are your production requirements, DRAGON company can provide corresponding products according to different application scopes.

Features of Corrugator Belt:

Describe of Corrugator Belt:

The Corrugator Belt (Corrugated cardboard conveyor belt) is undoubtedly one of the most important parts of the corrugated cardboard production line. Its quality has a decisive impact on the quality of corrugated cardboard and has always been of concern to carton factories and tile line manufacturers. The four main functions of Corrugator Belt(Corrugated cardboard conveyor belt) are: 1. Smooth cardboard transportation; 2. Straight line operation; 3. Uniformly distribute the pressure of the pressure system to the hot plate; 4. Ensure the dryness of the cardboard. Corrugator Belt (Corrugated cardboard conveyor belt)s are developed specifically for transporting cardboard and optimizing the drying process. They can continuously resist stress and achieve the longest possible service life. The patented weaving structure ensures the correct bonding and rapid drying of the board. The use of high-quality synthetic fibers enables the conveyor belt to quickly dissipate the moisture absorbed during the drying

Working principle of Corrugator Belt:

The conveyor belt applies pressure to the cardboard, causing it to stick to the surface of the heating plate, absorb heat and evaporate water vapor, and be absorbed and dissipated by the conveyor belt during operation.

Three reasons for choosing us

Double Dragon Fabric

World Market Leader

We are the world market leader in producing air slide fabrics and offer you high-quality fabrics.

No matter what production requires – we offer you the suitable product for every application!

High Quality

In order to produce high-quality air slide fabrics, we use a unique patented weaving technology. We only use high-quality raw materials.

We have cutting-edge production equipment, exquisite craftsmanship, rigorous management system, and rigorous quality inspection process.

Reliability

Double Dragon Fabric guarantee safety and reliability during your production processes.

We also offer you excellent customer service with our worldwide sales partners and service technicians – from the first contact to a comprehensive after-sales service.